Management Approach

The Company is steadfast in responsible operations towards all stakeholders. Under the policies spanning from sustainable procurement to ethics and business supplier guidelines. The criteria for supplier selection include supplier capacity and compliance with the relevant law and regulations. The Company promotes and supports its suppliers and develops supplier capability through procurement and responsible supply chain management in order to fulfill the constantly changing needs and expectation of customers, communities and society. Additionally, there have been support for additional agricultural product and organic product sales channels while taking into account the appropriate distance from farms to point of sales to preserve product freshness and development of work processes to reduce environmental impact. Furthermore, the Company realizes the importance of product traceability in order to promote sustainable raw material usage throughout the various projects.

Supplier’s Sustainability Management Processes

Procure and screen capable suppliers, in accordance to relevant laws and regulations and consideration of

– Prodcuction Capacity

– Quality

– Food Safety

– Traceability

– Sustainability Performance

Suppliers’ Risk Assessment

Foster and promote suppliers’ capability in responsible sourcing and supply chain management including Continuously assessing suppliers’ sustainability performance

Build and maintain a long-term relationship with suppliers, in alignment with sustainable development approach. Support to remunerate good performance, including sustainability performance

In 2024, the Agricultural products and animal products certified by external organizations were as follows:

| Sustainable Production Standards Certified Agricultural Products | |||

|---|---|---|---|

| Agricultural Crops | Standard | The coverage of products Certified | Purchasing volume vs. total raw material procurement |

Palm oil Palm oil |

RSPO | 45.87% | 15.86% |

Soybean Soybean |

RTRS, Pro terra, CRS | 76.08% | 13.22% |

Sugar Sugar |

BONSUCRO | 14.82% | 9.77% |

Cacao Cacao |

FSSC 22000, Rainforest Alliance, Fair Trade, GAP | 83.46% | 5.31% |

Coffee Coffee |

Rainforest Alliance, Fair Trade, UTZ | 16.61% | 13.42% |

Cereal (rice, wheat, barley, corn) Cereal (rice, wheat, barley, corn) |

BRC, HACCP, GAP | 35.04% | 14.99% |

Other products Other products |

GAP, Q Organic | 34.51% | 6.33% |

| Sustainable Production Standards Certified Animal Products | |||

|---|---|---|---|

| Animal Products | Standard | The coverage of products Certified | Purchasing volume vs. total raw material procurement |

Aquaculture products Aquaculture products |

ASC, BRC, GHPs, HACCP, BAP, GDST, GAP | 50.98% | 5.62% |

Cattle products Cattle products |

BRC, BBFAW, GAP, Livestock OK, AAWCS | 32.75% | 1.99% |

Dairy products Dairy products |

BRC, GAP, GMP, AAWCS | 20.19% | 20.56% |

Swine products Swine products |

BRC, BBFAW, GAP, Livestock OK, AAWCS | 68.41% | 35.90% |

Poultry products Poultry products |

BRC, BBFAW, GAP, Livestock OK, AAWCS | 65.05% | 26.48% |

Wild fisheries products Wild fisheries products |

MSC, BRC, MarinTrust, GDST, GAP | 43.94% | 9.45% |

Key Projects in 2024

In accordance with sustainable procurement policies, the Company supports activities and implements food security projects through 3 main approaches as follows:

Management Approach for Food Security

Food Availability

Access to safe and nutritious food to eliminate hunger and malnutrition

Food Utilization

Developing environmentally friendly food production processes which preserves natural resources through sustainable agriculture, an approach to food sufficiency and quality

Food Accessibility

Raise standards for delivering products and services which uphold quality, safety, and hygiene standards

1. Food Accessibility

Provide flood victims with access to quality food and drinking water

Under the “Public mind” project, CP ALL collaborated with the area operations office, public mind team, Office of Government Coordination, jet ski team, and Special Disaster Relief Club to provide onsite assistance and relief to flood victims across the country through delivering clean drinking water, bread, rice, canned fish. The Company assisted in disaster mitigation and good hygiene promotion among disaster victims in Nan Province, Phrae Province, Chiang Rai Province, Sukhothai Province, Songkhla Province, etc. In 2024, a total of 873,897 victims were provided access to safe food and drinking water, with a total support value of 1.60 million Baht.

Under the ongoing project “CPRAM We Care project: Caring for the community” for the 4th year, the Company formed a central kitchen in disaster affected areas to deliver ready-to-eat food, bakery items and drinking water to victims of every crisis. For instance, over 5,000 care bags were distributed among flood victims in Chiang Rai and Nan provinces to assist and alleviate their suffering. Main target groups where assistance was provided to include disaster victims, those in need, the impoverished, and vulnerable groups. Vulnerable groups have also been provided with safe food and drinking water on various other occasions. In 2024, a total of 50,438 people received assistance in access to safe food and drinking water equivalent to a support value of 1.7 million Baht.

CP Axtra has deployed teams to assist flood victims in the northern, northeastern, and southern regions, covering 14 provinces. They have provided consumer goods, cleaning equipment, and essential items worth over 1.5 million Baht to the affected communities. Additionally, they have contributed to the restoration of homes and buildings impacted by the flood.

Providing access to quality food and drinking water among children, youth, the impoverished and vulnerable groups

CP ALL in collaboration with CONNEXT ED, a foundation for educational support, supports schools under OBEC through organizing projects including Wonderland Learning Park: Father’s Story, to create a learning environment for the production of drinking water which is sufficiently clean, safe, and hygienic, in addition to income generation and opportunities to learn and practice vocational skills. The Company provided access to safe food and drinking water

to a total of 372 households accounting for 1,426 people.

CP Axtra ongoing project “Good food for brothers and sisters” year 7 provides support valued over 2.6 million Baht with the intention to delivery over 3 million meals quality lunch ingredients throughout the 2024 academic year to over 38,555 students in over 208 schools across 77 provinces nationwide. This initiative provides access to good, healthy, safe, and nutritional food.

CPRAM delivers ready-to-eat food, including Jade Dragon Dim Sum, Le Pan Bakery, and drinking water to children and youth at Ban Rajavithi Girls’ Home under the “Krua Pan Im” project, an initiative to distribute boxed lunches to children of Baan Rajavithi. In 2024, a total of 450 children and youth were supported through access to safe food and drinking water, with a support value of 25,000 Baht.

Delivering opportunities for good health to children and youth

“Bathroom for Children” Project from “Donated 7-Eleven Stamps”

Because education starts from the bathroom, problems of inadequate and unhygienic bathrooms are an obstacle to children’s education and health. Thus, the Company collects donated 7-Eleven Stamps from donating customers nationwide to improve school bathrooms throughout the country, including schools impacted by flooding. This approach grants the affected students an opportunity to access amenities vital towards basic livelihood and supports equal opportunities for children in remote areas in terms of good hygiene and reduction in various infectious disease risks. In 2024, the Company renovated bathrooms for schools in local communities and flood-affected schools, totalling over 100 locations in multiple regions.

2. Sustainable Agriculture Commitment (Food Availability)

| Programs to reduce water consumption | |

|---|---|

| No-Till/Conservation Agriculture in Rained Areas |

|

| Management and Technology |

|

| Programs to Reduce Environmental Pollution | |

| Production of Organic Products |

|

| Use of “Smart” Pesticides |

|

| Enclosed Production Systems: Aquaculture |

|

| Programs to Protect Soil Health | |

| Low Frequency and Intensity of Tillage |

|

| Programs to Prevent the Destruction of Ecosystems | |

| Certifications that Ensure Deforestation-Free Production |

|

| MSC or ASC Certifications which Ensure Sustainable Production |

In addition, CP ALL is aware of the importance of conserving marine resources and promoting sustainable fishing and aquaculture, a key factor in assuring food security and a healthy marine ecosystem. Due to the mentioned rationale, the Company places importance in supporting MSC and ASC products which uphold international standards accepted globally through source verification. The MSC and ASC certified products offer consumers increased product alternatives

|

| Programs to Reduce GHG Emissions | |

| Reduced Transport Distances Through |

|

| Local Products Offerings in Retai |

|

| Local Products Offerings in Retail |

|

3. Food Utilization

ALL FOOD TECH Testing Center

Under the supervision of the Product Quality Assurance Division, was established to support SMEs with knowledge and capability to develop production standards in addition to ensuring standardized, high quality, and safe products for consumers. Training and advice workshops were organized for production and product development in addition to offering food analysis services at the laboratory. The laboratory, which operates under the internationally recognized standard ISO/IEC 17025 : 2017, is intended to assist SMEs with developing and introducing high quality and safe products into society.

Animal Welfare Standards Project

CP ALL in conjunction with Charoen Pokphand Foods Public Company Limited, the Company’s main raw material supplier, operates under policies and guidelines for animal welfare management to deliver raw materials certified to meet quality and food safety standards from leading international institutions and organizations. The mentioned institutions include Business Benchmark on Farm Animal Welfare (BBFAW), Marine Stewardship Council (MSC), etc.

CP Axtra is committed to supporting farmers who produce eggs from cage-free hens. In this regard, the Company collaborates with King Fresh Farm, both a business ally and the first Thai SME producer of quality organic chicken eggs to be certified by standards from both Europe and America, including EU, NOP & USDA (USA). The Company also cooperates with egg farmers and related agencies to produce free-range organic chicken eggs sold under the brand “Aro Gold”. Through providing farmers with training, developing a process for cage-free egg production, and campaigns to disseminate knowledge to customers and the public, customers have an alternative high quality well-being product to choose from. Eggs are free from antibiotics, hormone boosters, and growth accelerating substances to increase safety and nutritional value. Additionally, cooperation with major egg producers like CPF has been established with the aim to increase cage-free chicken eggs every year, thus enabling increasingly affordable egg volumes from happy hens.

Product Nutritional Value Guideline Project

The Company establishes standards and criteria for developing food and beverage products under the Company’s private brand to promote health and nutrition offered to consumers. Support projects have been initiated throughout processes involving cultivation, production, receiving products, product organization and distribution, and sales and services in 7-Eleven, Makro and Lotus’s stores.

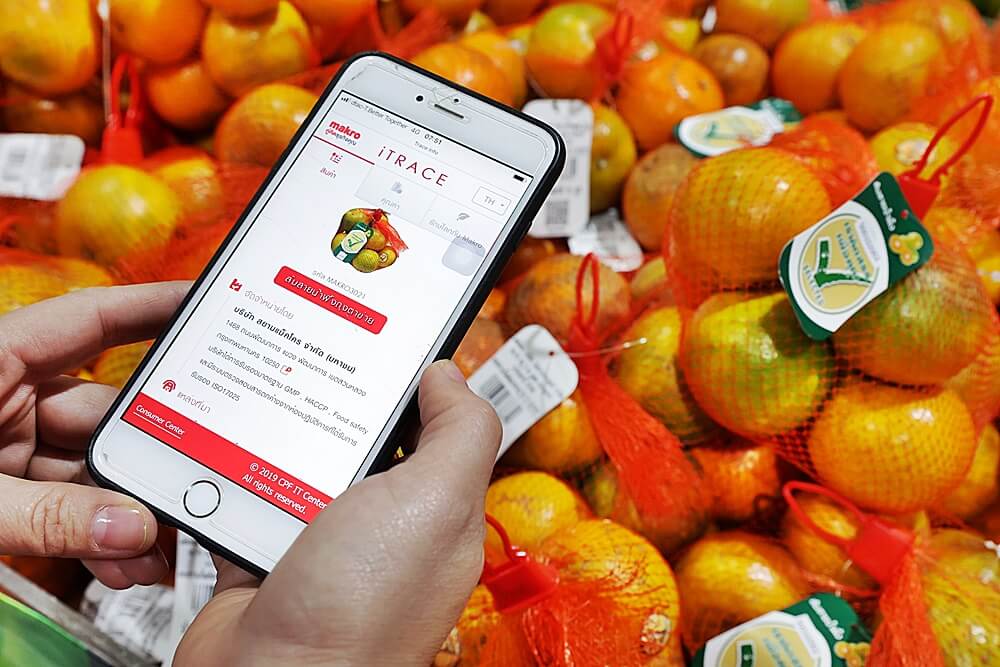

Traceability Project

CP Axtra provide food safety and traceability policies for fresh food and quality ingredients through the application of QR Code technology, which efficiently connects to a database of over 14,000 traceable products. To allow customers to back trace and access in-depth product details comprising production source, nutritional information, and food menus, Makro provides the “Makro i-Trace” system while Lotus’s provides the “e-traceability” system. The database for traceability and nutritional information provided by Makro and Lotus’s is continuously being developed and expands to encompass additional products in various groups including bakery, processed foods, etc. The traceability technology adoption has expanded to cover Makro’s overseas branches, including branches in the Union of Myanmar.

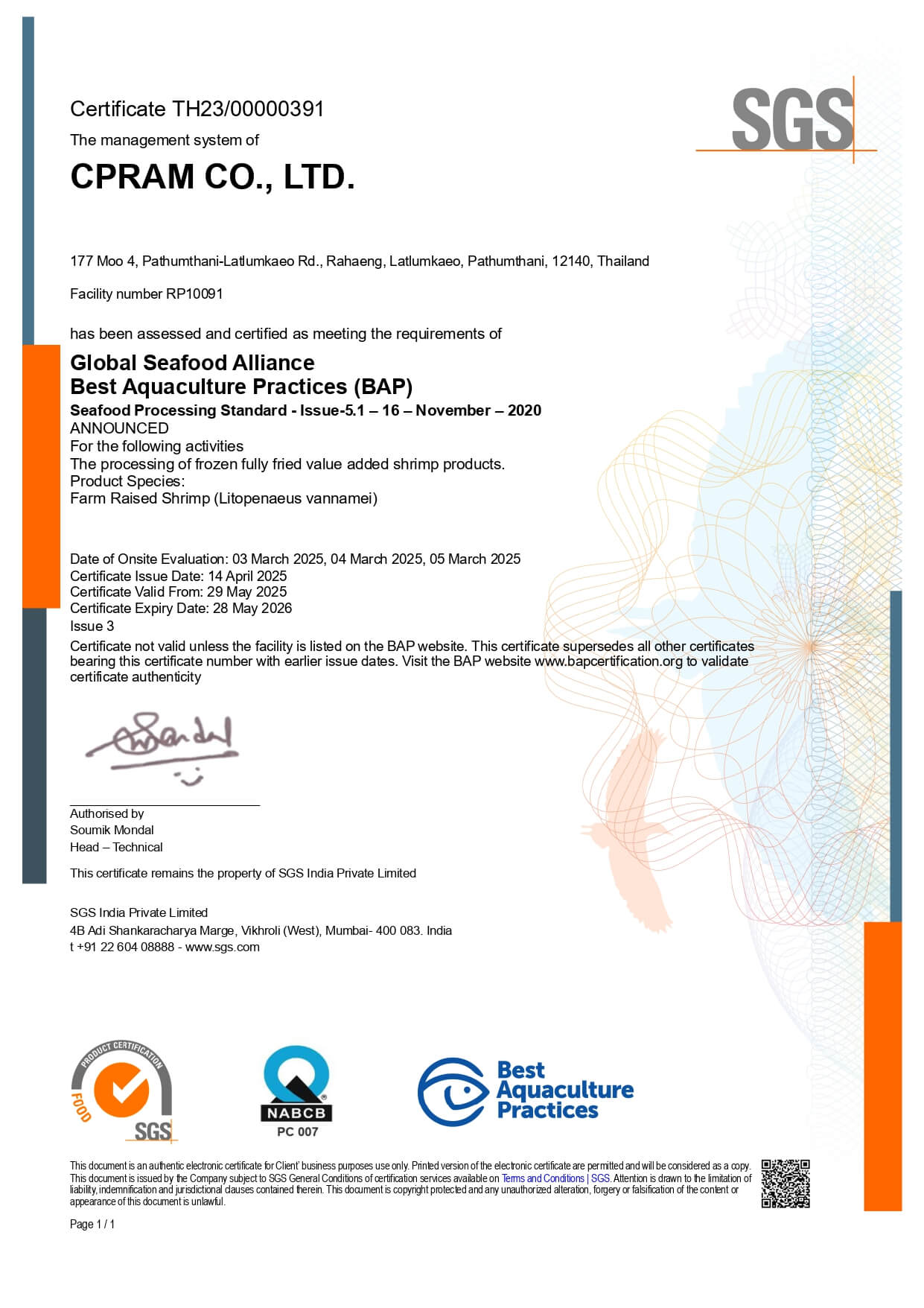

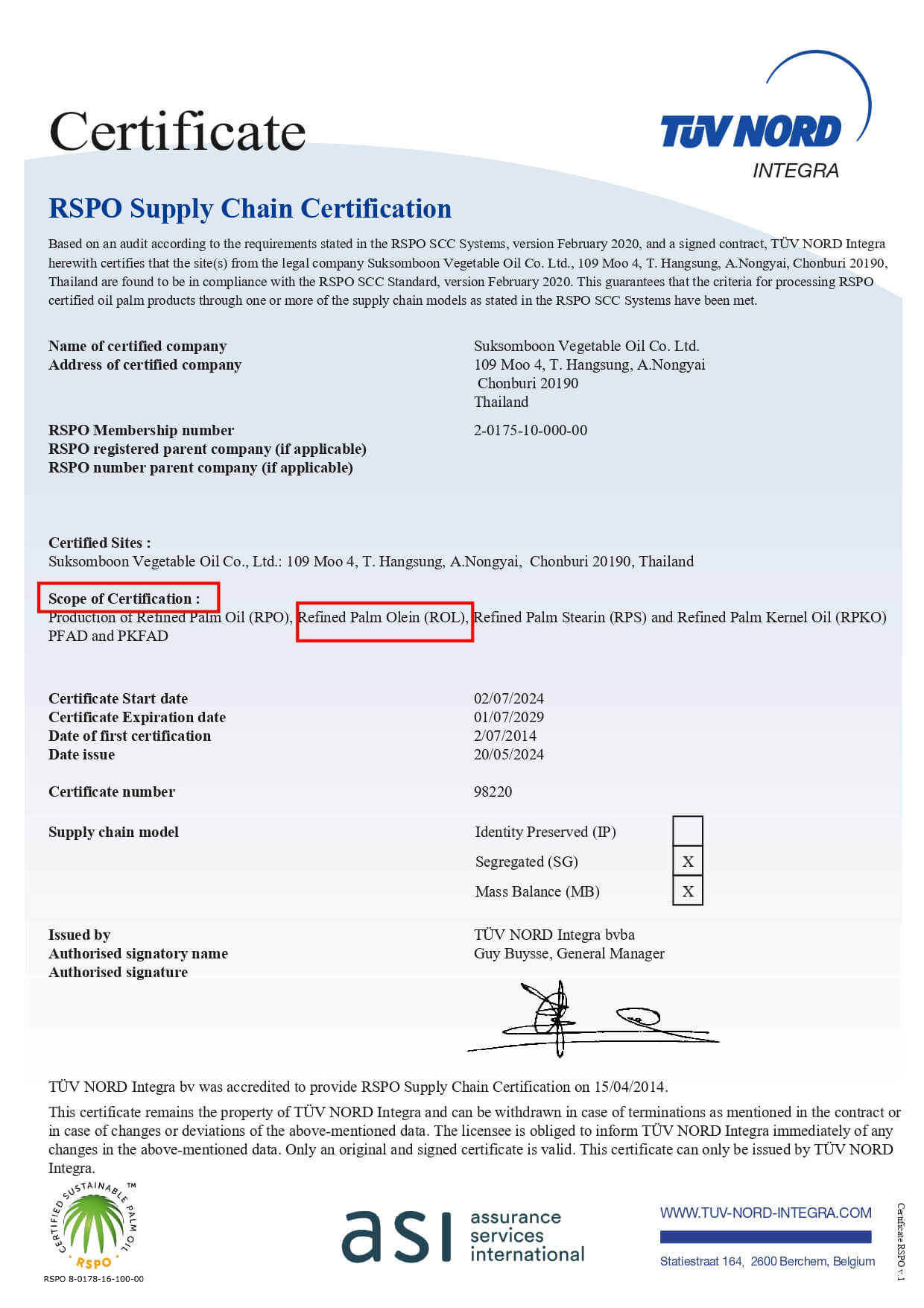

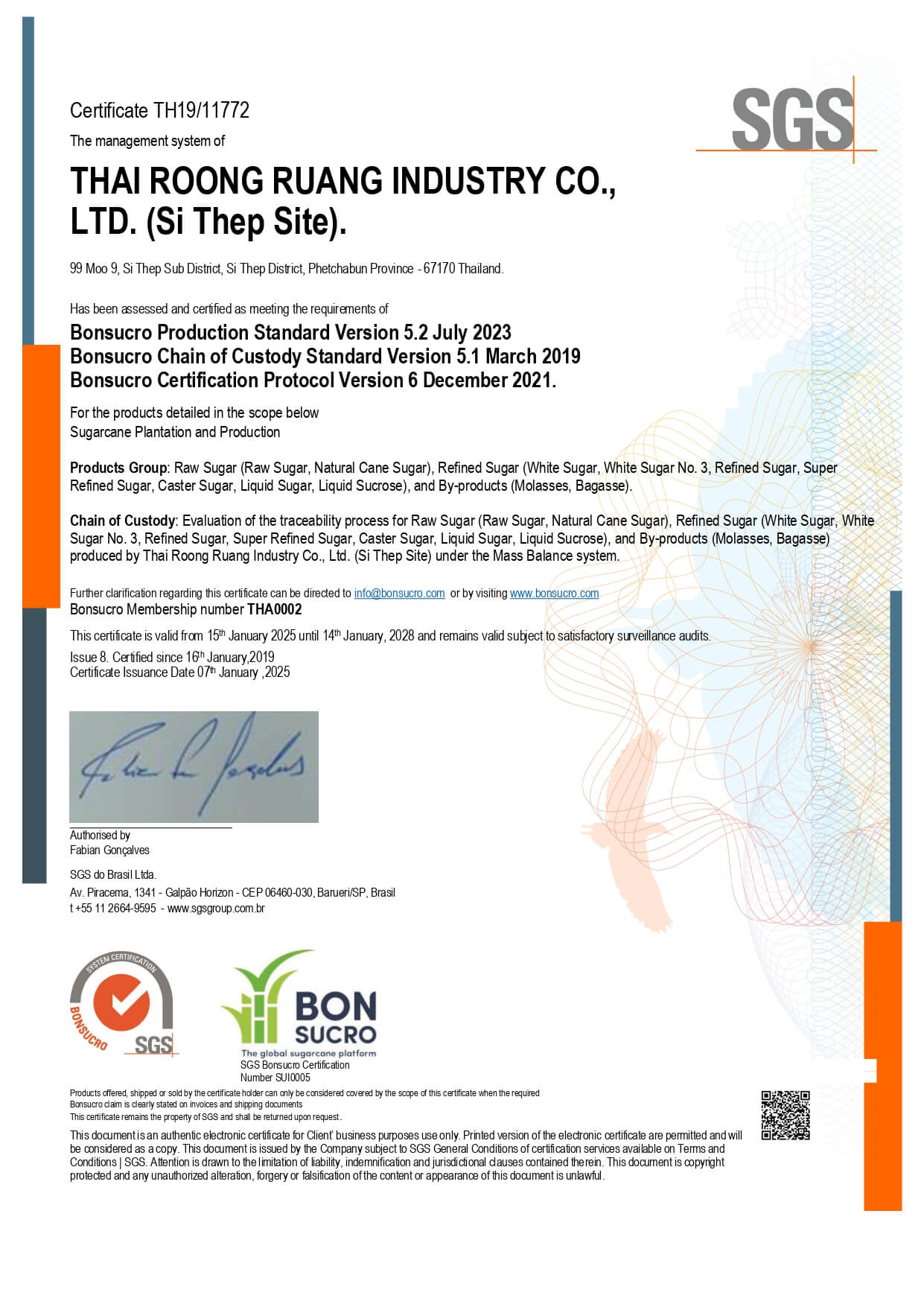

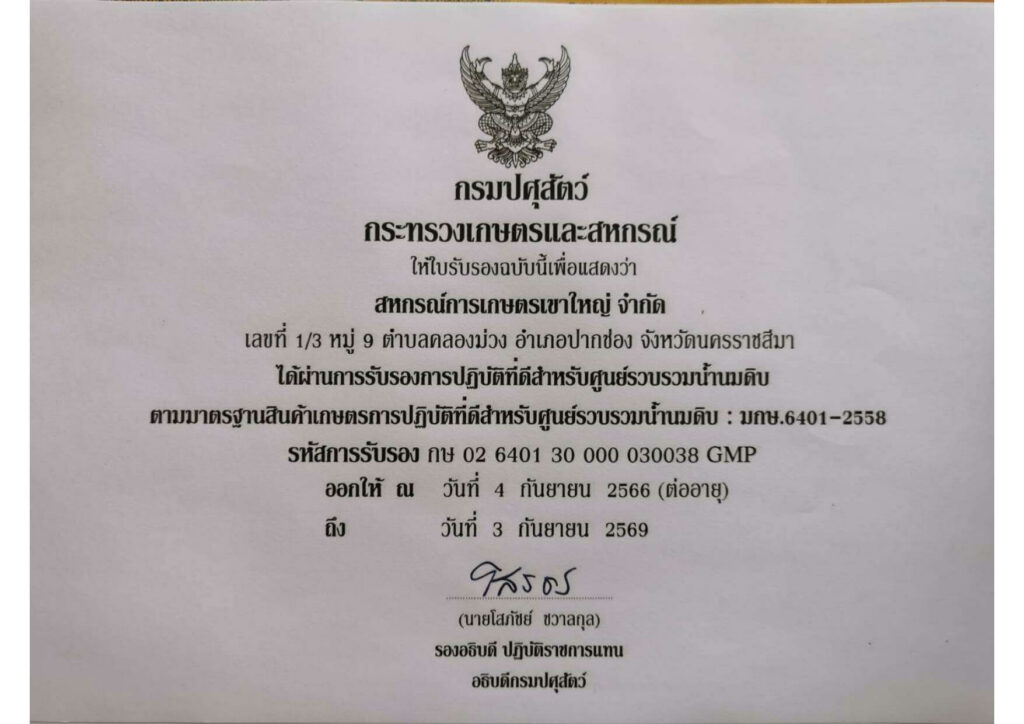

Example for Certification or Accreditaiton

Best Aquaculture Products (BAP Certificate)

Palm Oil (RSPO Certificate)

Bonsucro

GMP (Dairy Products)

GMP (Dairy Products) GAP (Dairy Products)

GAP (Dairy Products)

Bon sucro

Bon sucro Rainforest Alliance

Rainforest Alliance RTRS

RTRS RSPO

RSPO Rainforest Alliance

Rainforest Alliance