Sustainable Waste Management

Key Performance in 2024

Waste volume capable of reuse of total waste quantity

Waste management from business operations (Alternative Purpose) from the total amount of waste

764 schools, 89 entrepreneurs, 64 network communities and 3 offices participated in the “Ton Kla Rai Tung” project. Separated of waste sent it into the appropriate management process

Key Progress in 2024

Integrated food product write-off reduction project (OA Ordering) reduced the amount of food excess or waste by 7,827 tonnes

Surplus food donation to foundations project delivered over 770 tonnes donated to 1,849 communities

Ongoing project: Eat without leaving each other

Adding value to production process by products project volume reduction loss of food in the production process 140 tonnes per year

Ton Kla Rai Tung project continuous expansion to community networks, entrepreneurs and 920 offices

Supporting the SDGs

SDG 3 Ensure healthy lives and promote well-being for all at all ages

3.9 Substantially reduce the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination

SDG 6 Ensure availability and sustainable management of water and sanitation for all

6.3 Improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials

SDG 11 Make cities and human settlements inclusive, safe, resilient and sustainable

11.6 Reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management

SDG 12 Ensure sustainable consumption and production patterns

12.3 Halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains

12.4 Achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and

significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

12.5 Substantially reduce waste generation through prevention, reduction, recycling and reuse

Performance Against Goal

Results of the “Double Materiality Matrix”

Sustainable Dimension

Impact level for application in business operations

Progress against Short-term and Long-Term Goals

Reduce surplus or leftover food destined for disposal and minimize waste generated from company operations to achieve Zero Waste to Landfil

*Remarks: This graph illustrates CP ALL’s systematic and sustainable waste management efficiency in reducing landfill waste. In 2024, the company managed to utilize 75.05% of its waste, leaving only 24.95% for landfill disposal. This demonstrates significant progress toward the company’s goal of achieving zero landfill waste by 2030

Performance Summary 2024

Total amount waste

Waste Disposal Data Coverage

Total waste per revenue

Total food loss and food waste

Waste disposed and repurposed

Food loss and food waste Intensity

Waste disposed at landfills

Total food loss and food waste (tonnes) classified by Business activities or Life cycle Stage

Total food loss and food waste classified by food category

Food waste disposed and repurposed

Food waste disposed and repurposed classified by Destination

Food Loss and Waste Management Strategy Project

| Project type | Project title |

|---|---|

Food loss, food waste and waste measure project Food loss, food waste and waste measure project |

|

Food loss, food waste and waste reduce project Food loss, food waste and waste reduce project |

|

Food Loss, Food waste and Waste Recycling Project Food Loss, Food waste and Waste Recycling Project |

|

Risks and Opportunities

The United Nations Environment Programme (UNEP) released the “Food Waste Index Report 2024,” highlighting that over one billion meals are wasted daily, with household waste accounting for the largest proportion. Additionally, the UNEP’s “Global Waste Management Outlook 2024” (GWMO 2024) revealed global waste and waste management trends, predicting that by 2050, waste volume will increase by two-thirds and waste management costs will nearly double. This supports the push toward zero waste and a circular economy model. The inefficient use of resources contributes to waste and food loss throughout the supply chain, from production and harvesting to transportation and consumption. Food waste and loss significantly contribute to greenhouse gas emissions, including methane and carbon dioxide, as well as pollution of water sources and air quality, such as lleachate, hydrogen sulfide gas, and methane gas. These issues may also have long-term health impacts on surrounding communities.

For this reason, the Company prioritizes efficient food waste management by implementing policies to reduce food waste caused by overproduction, as well as general waste from Company operations. The aim is to minimize food loss during transportation, distribution, and storage, mitigate impacts from surrounding ecosystems, and promote community health. The Company repurposes waste generated from production processes, utilizing it as alternative raw materials to create economic value and provide a sustainable solution to food waste issues. These efforts reflect the Company’s commitment to promoting social and environmental development while supporting the goal of reducing the impact on natural resources and fostering a more balanced future between humanity and the environment.

Management Approach

CP ALL Public Company Limited and subsidiaries (“the Company”) are committed to sustainable waste and food waste management to prevent and reduce pollution that may impact air, water, and soil quality, potentially affecting the health of nearby communities. The Company aims to achieve zero waste to landfill by 2030 while supporting the United Nations Sustainable Development Goals (SDGs), particularly Goal 12. This commitment is pursued through partnerships with business allies to manage food surplus, reduce food loss, and handle food waste, as well as other waste generated from business operations. The Company adopts the “1P3Rs” approach from the Food and Agriculture Organization of the United Nations (FAO), emphasizing (1) Prevention, (2) Reduction and Optimization, (3) Reuse, and (4) Recycling. This initiative is designed to mitigate risks associated with excessive resource consumption in production processes and to minimize environmental impacts.

The Company has implemented a comprehensive waste management plan by establishing a database that categorizes waste data according to activities in the supply chain. This includes processing and production, transportation and distribution, retail, and delivery to consumers. These data enaable the Company to analyze resource consumption and potential waste generation both internally and externally. Additionally, the data allows for the classification of waste composition, proportions, and types, facilitating the development of effective strategies and measures to minimize losses throughout the supply chain. This initiative supports sustainable business development and promotes a circular economy by ensuring the efficient and long-term use of resources.

Food Loss and Food Waste

The Company applies food management strategies to reduce food waste based on guidelines from the Food and Agriculture Organization of the United Nations (FAO) in collaboration with the United Nations Environment Programme (UNEP). These principles are integrated into business operations through various initiatives and measures, as outlined below.

Prevention

Reduction

Reuse

Recycling

Measuring, analyzing, and developing a database

Collaborating with communities and suppliers in garbage and waste management

Raising awareness and encouraging the public to change consumption behavior

1. Projects under the measures to prevent food waste and waste generation from the source

Ongoing Project: The integrated reduction of food product write-offs

The Company analyzed historical sales data alongside best-selling and remaining products using the “Graphic Ordering Terminal (GOT)” device. This helps 7-Eleven employees check stock levels, manage inventory, and adjust orders according to real-time conditions, such as special promotional periods. In 2024, the Company successfully reduced losses from product write-offs by 1.60%, equivalent to a value of 178 million Baht.

Ongoing Project: Reduction of waste in the production process – Year 10 (under the Zero Waste to Landfill initiative)

CPRAM Company Limited places great importance on strict compliance with waste management regulations and continuously enhances operational efficiency. In 2024, the Company improved production processes and equipment to minimize raw material waste and food surplus. This includes reducing waste from raw material trimming, implementing ultrasonic-powered trimming machines to minimize losses, and developing machinery to prevent product drops on the production floor.

2. The Project under the Reduction Measure to Maximize Benefits

Ongoing project: managing surplus food via the Food to Merit Foundation – Year 4

The Company partners with various foundations to distribute surplus food from 7-Eleven stores to communities, social organizations, charities, and underprivileged individuals. Each food donation undergoes a thorough quality check, ensuring food integrity, freshness, and high quality. The food items also carry an FDA (Food and Drug Administration) certification, clearly indicating expiration dates. The donated food includes bread, sandwiches, milk, vegetables, instant food, fruits, and cooked meals.

In 2024, the project expanded to 630 7-Eleven stores across 46 districts in Bangkok and provinces such as Prachuap Khiri Khan, Phuket, Chonburi, Samut Prakan, Pathum Thani, Chiang Mai, Chiang Rai, and Nonthaburi. The initiative is expected to deliver 3,162,468 meals to 1,849 communities while reducing food waste by 700.49 tonnes per year.

Ongoing project: Black Soldier Fly (BSF) – Year 2

CP Axtra through Makro and Lotus’s has expanded the knowledge transfer on protein insect farming from the Northeastern region to all regions across Thailand under the “Turning Waste into Benefit” project. This initiative promotes the use of surplus food from CP Axtra, which is provided to 272 farmers as raw material for rearing Black Soldier Fly (BSF) larvae, a species safe for plants and communities. The project includes training sessions on BSF production and utilization across 7 provinces in 5 regions of Thailand: Chanthaburi, Sakon Nakhon, Roi Et, Phra Nakhon Si Ayutthaya, Phetchabun, Surat Thani, and Si Sa Ket, totaling 472 farmers

In 2024, the project is expected to deliver over 912.26 tonnes per year of unsold food to support this initiative.

Project for donating high-quality sample products remaining from quality research

CP ALL, Product Quality Assurance Office, contributes to a sustainable society by donating high-quality sample products remaining from testing to the Scholars of Sustenance (SOS) Foundation and the Kredtrakarn Protection and Occupational Development Center. These products are utilized to their fullest potential, such as using coffee beans for vocational training or distributing them to those in need. To ensure that all donated products are of high quality and safe, the Company conducts strict quality inspections, collaborates with suppliers to monitor donations at every stage, and records detailed information to ensure safe delivery to recipients. In 2024, this initiative has helped reduce food waste by 1.144 tonnes.

Ongoing Project: Good People CPRAM x SOS Food Rescue Kitchen – Year 4

CP RAM, in collaboration with the Scholars of Sustenance Foundation (SOS), has launched the “Good People CPRAM x SOS Food Rescue Kitchen” project, reaching out to communities in Lamphun and Pathum Thani provinces. The initiative establishes kitchens to create new dishes from surplus food to reduce food waste and excess food issues-food that exceeds demand but remains consumable. These meals are delivered to communities and vulnerable groups. In 2024, the project has provided 4,340 meals and helped reduce carbon dioxide emissions from surplus food by 2,622.57 kgCO2e (kilograms of carbon dioxide equivalent). This project is part of the “Good People of CPRAM” initiative, which aims to instill good values in employees, encouraging them to be role models, promote positive thinking, do good deeds, and contribute to society and the nation.

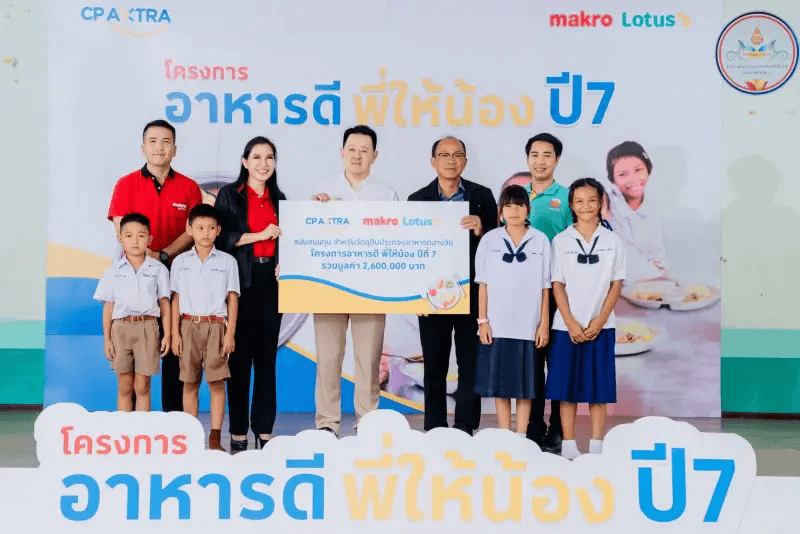

Ongoing Project: Good Food for Kids Project – Year 7

CP Axtra supports school lunch programs by providing funding for the purchase of high-quality ingredients to prepare nutritious meals for students in underprivileged schools across all 77 provinces in Thailand. This initiative ensures that students have access to safe, nutritious food that supports their healthy growth and development, enhancing their ability to learn effectively. This year, CP Axtra has also organized a special activity, “Longan Sharing Happiness…Bringing Joy to Communities” for 5 consecutive years. This initiative helps longan farmers earn a stable income by providing selling space in all Makro and Lotus’s stores. For every kilogram of longan sold, 1 Baht is donated to support quality ingredients and fresh food for 172 schools nationwide as part of their lunch programs. Additionally, the initiative promotes student health and well-being by introducing pilot programs in 20 schools, educating teachers and students on food waste management. The project includes experimental Black Soldier Fly (BSF) farming, which helps reduce food waste while serving as a model for local communities.

Impact and Benefits

Number of beneficiaries with improved access to food

Total support value

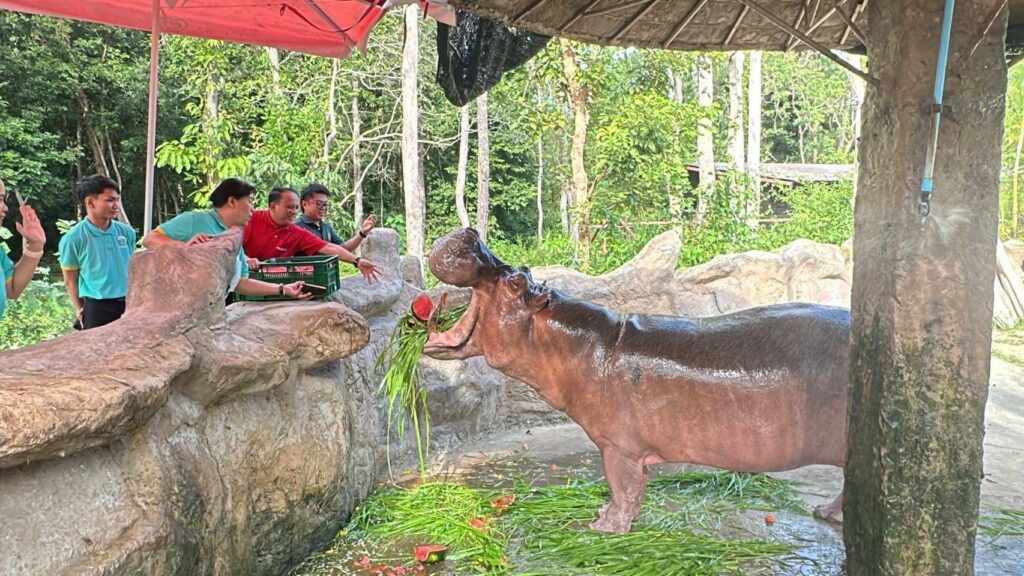

Animal Feeds Processing Project

CP Axtra through Makro and Lotus’s have signed a memorandum of understanding (MOU) with the Department of National Parks, Wildlife, and Plant Conservation to donate surplus food including vegetables, fruits, and excess food from Makro and Lotus branches to wildlife breeding stations, wildlife rescue centers, and Bueng Chawak Wildlife Management Development Center under the care of Department of National Parks, Wildlife and Plant Conservation. This initiative promotes efficient use of natural resources, maximizes benefits, reduces food surplus, and alleviates the annual budget burden for wildlife welfare.

In 2024, Makro and Lotus’s delivered food donations to 27 wildlife rescue centers and zoos nationwide. Additionally, they signed an MOU with the Forest Industry Organization to further support the well-being of elephants at the National Elephant Institute under Royal Patronage by donating edible surplus food, including vegetables and fruits, from 10 branches in Chiang Mai, Lampang, and Krabi provinces. This initiative aligns with the environmental goal of achieving zero food waste by 2030. As a result, the Company has diverted nearly 2,000 tonnes of surplus food from landfills, repurposing a portion as animal feed.

3. Project Under the Reuse Production Measures

Ongoing Project: Adding Value to By-products from the Production Process – Year 6

CPRAM repurposes surplus raw materials from production losses to create new value-added products, helping reduce food waste. The development is to add value to new products, such as garlic bread made from bread crusts and blueberry cheesecake products.

Impact and Benefits

Reduced food loss in production processes

(105 tonnes of garlic bread, 35 tonnes of blueberry cheesecake)

no cost to manage food waste

Increased product value, generating sales of

(19 million Baht from garlic bread,

89 million Baht per year from blueberry cheesecake)

4. Project Under Recycling Measures per Circular Economy Framework

Ongoing Project: ZERO Waste to Landfill – Year 9

CPRAM carries out various projects to manage waste and leftover materials utilizing the 3Rs (Reduce, Reuse, Recycle) waste system in an integrated manner. The project implementation yields 100% waste management, which can be categorized as follows:

Impact and Benefits

Waste elimination without the landfill process

Generate income from waste and excess materials on average

Reduced greenhouse gas emissions

Separated of waste for recycle processing

| Type | Recycling Volume | Management |

|---|---|---|

Breadcrumbs Breadcrumbs |

Animal Feed Animal Feed |

|

Food loss Food loss |

Animal Feed Animal Feed |

|

Sludge from wastewater treatment Sludge from wastewater treatment |

Bio fertilizers and soil conditioners Bio fertilizers and soil conditioners |

|

Plastic waste Plastic waste |

Plastic pellets Plastic pellets |

|

Glass and plastic bottle waste Glass and plastic bottle waste |

Recycled Recycled |

|

Hazardous waste Hazardous waste |

Used as a raw material in cement factories Used as a raw material in cement factories |

|

General waste General waste |

Fuel RDF in power plants Fuel RDF in power plants |

Ongoing Project: “Turning Waste into Value (EM Bio-fermented Solution)” – Year 14

CP Axtra repurposes food waste from distribution centers such as unsellable and inedible vegetables and fruits-into Effective Microorganism (EM) bio-fermented solution for cleaning grease stains within distribution centers. This initiative has been running since 2010 and continues to the present. For the performance outcome in 2024, a total of 593.53 tonnes of food waste has been reduced by converting into EM bio-fermented solution, which has been donated to Bangkok Metropolitan Administration (BMA).

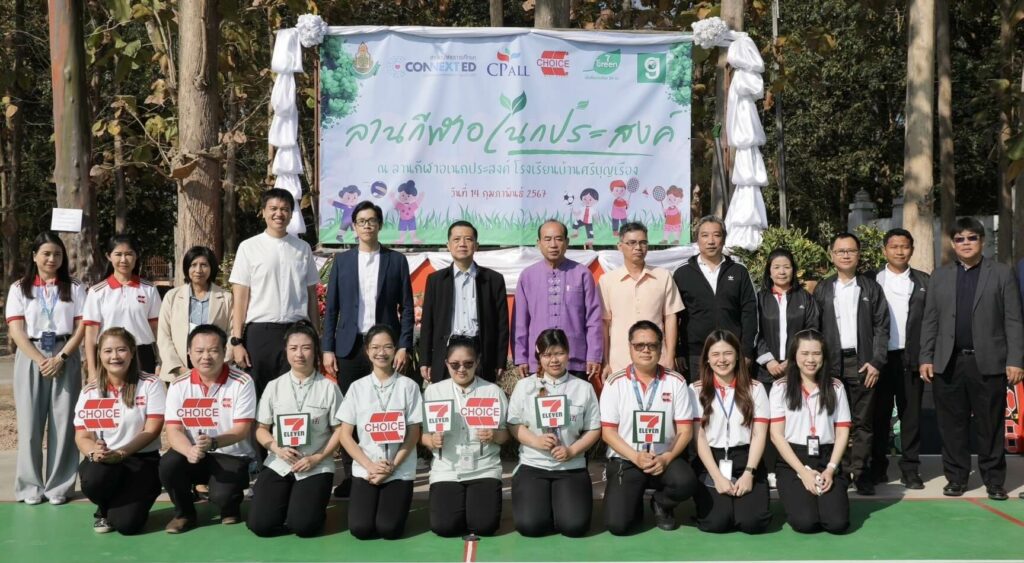

Ongoing Project: Green Multipurpose Space – Year 2

CP ALL supports the “Green Multipurpose Space” initiative by utilizing orphan plastic waste as a construction material mixed with concrete for flooring. This reduces the use of stone and sand in the concrete mixing process, leading to Green Innovation that helps conserve natural resources and addresses community waste issues. Additionally, this project expands into the development of the Eco-Concrete Innovation Learning Center, promoting lifelong learning while creating supplementary income, contributing to sustainable environmental solutions based on the circular economy concept.

In 2024, CP ALL has donated 5 Green Multipurpose Spaces to communities and schools, including: Ban Nong Um Community, Maha Sarakham Province and Koh Pha-ngan School, Ban Tai Subdistrict, Pha-ngan District, Surat Thani Province. This initiative has diverted 8.7 tonnes of orphan plastic waste from the environment, equivalent to a reduction of over 8.95 tCO2e

CP ALL, in collaboration with Choice Mini Store and Green Road, has donated “Green Multipurpose Spaces” made from orphan plastic waste collected from 7-Eleven stores and mixed with eco-concrete to Ban Sri Bunruang School in Chiang Mai Province and Ban Nam Yoi School in Lamphun Province, reducing 1,357 kilograms of plastic waste from landfills. Additionally, orphan plastic waste, aluminum foil bags, and plastic bags were repurposed into 12 park benches, diverting 300 kilograms of plastic waste from landfills. Furthermore, 750 plastic bottle caps and 600 shimmering plastic bags were recycled into trophies made from recycled plastic for the Volleyball Championship Finals in 2024, helping to eliminate 30 kilograms of plastic waste from landfills.

Impact and Benefits

Reduced orphan plastic waste by a tota

Reduced greenhouse gas emissions

Participated in the project

Ongoing Project: Thap Sakae Green café for a Sustainable World – Year 2

The project was initiated as a comprehensive waste management odel under the “Bin-Free Seedling” project, this initiative has expanded into an environmental learning center and a vocational skill evelopment hub for students, now known as “Thap Sakae Green Café for a Sustainable World.” Located at Thap Sakae School in Prachuap Khiri Khan Province, the café serves as a learning center, tourist attraction, and new check-in spot for Thap Sakae District. It integrates waste management education into the school’s curriculum as a “local course”, further developing and enhancing café operations under the “Green Café Store Concept.”

5. Measurement, analysis and database preparation

Elevate database management based on international standards

The Company measures and analyzes food waste composition from business activities and has categorized data into 7 groups.

Plants, vegetables and fruits

Meat and seafood

Dairy products

Ready-to-eat food

Beverage

Processed food

Bakery products

In 2024, the Company generated a total food waste volume of 68,147.15 tonnes, by which the Group of plants, vegetables and fruits food waste category accounted for the highest volume at 21,932.41 tonnes, representing 32.18% of total food waste volume in 2024 (the proportion of food waste by group is presented in the Performance Summary 2024).

6. Collaborating with Communities and Suppliers in Garbage and Waste Management

Ongoing Project: “Bin-Free Seedling” for Schools and Bin-Free Community - Year 5

CP ALL Public Company Limited, in collaboration with schools under the CONNEXT ED Foundation for Educational Advancement, that are supported by the Company, focuses on sustainable waste management through the “Bin-Free Seedling” initiative. This program emphasizes waste separation, recycling, and biodegradable materials, minimizing actual waste and reducing the need for garbage bins, ultimately achieving a “bin-free” state. The initiative also collaborates with local vendors around schools to eliminate the sale of items that generate orphan waste, such as straws, paper, and single-use plastic cups. In 2024, an additional 21 schools joined the initiative, bringing the total number of participating schools across 5 cohorts to more than 524 schools. These schools have become Bin-Free Schools and are now sharing knowledge with Bangkok Metropolitan Administration (BMA) schools, with plans to extend the project to all schools under the CONNEXT ED Foundation. Furthermore, the initiative is being expanded into “Bin-Free Communities” to promote community waste management, such as in Bang Bua Community (along Lat Phrao Canal) under Bang Khen District Office, Bangkok. The project also repurposes orphan plastic waste into eco-friendly bricks to help mitigate waste accumulation in popular tourist areas, such as Koh Phangan School in Ko Phangan District, Surat Thani Province.

Impact and Benefits

Reduced waste volume

Reduced greenhouse gas emissions

Participated in the project

Ongoing Project: “e-Waste in the Right Place” at Lotus’s

Lotus’s, in collaboration with True Corporation, expanded electronic waste collection points at 19 Lotus’s branches, including Fortune Town, Ladprao, Bangkapi, Wang Hin, Sukhumvit 50, Ramintra, Sukhapiban 1, Seacon Square, Prachachuen, Laksi, Liap Khlong 2, Pinklao, Bang Khae, Rama 2, Rama 3, and Rama 4, as well as Lotus’s Head Office, Nawamin, Rattanathibet, Bang Yai, and Bang Kruai-Sai Noi. This initiative serves as a community connector, encouraging proper electronic waste separation, such as recycling obsolete mobile phones, computers, and printers. In the past year, 49 kilograms of electronic waste were collected, resulting in a reduction of 0.93 tonnes of carbon dioxide emissions, equivalent to planting 103.57 mature trees.

7. Raising Awareness and Encouraging Behavioral Change in Consumer Habits

Ongoing Project: Raising Awareness on Food Waste

CPRAM has continuously raised awareness about food waste issues through the Facebook page, “Thai Society Without Food Waste,” and the group “Eat It All, Zero Food Waste.” These platforms serve as educational channels for food waste management and reduction. Currently, the Facebook page has over 30,039 followers, and the group has more than 1,223 members. Additionally, CPRAM organizes the “CPRAM FOOD STATION” initiative to promote food waste reduction awareness in society. The program educates people on meal planning, food preparation, and cooking in appropriate portions to prevent food waste. The Company also encourages reducing sugar, fat, and salt intake for better health. The initiative aims to drive behavioral change and enhance food security.

Ongoing Project: Color Waste Separation Bags, Encourage Participation, Drive for Sustainable Environment

Lotus’s develops branding, recyclable product ackaging, including Grade A Lotus’s brand garbage bags which not only uphold quality standards and safety, but is available at competitive prices. The bags are available in different color coding per Bangkok’s waste separation principle, namely yellow bags for recyclable waste, blue for general waste and green bags for organic waste or food waste. The mentioned approach facilitates ease in separating household wastes in preparation for effective collection management. Waste collection points are also available for respective waste collection and transfer to relevant agencies for recycling. This serves as an approach to further generate value and provide societal benefits.

The “No Mixed Waste x Turning Waste into Value” Project

CP Axtra, through Makro and Lotus’s, collaborated with the Bangkok Metropolitan Administration to segregate waste from over 400 branches, both large and small, across Bangkok. The project began as a pilot in 9 districts of eastern Bangkok and was subsequently expanded to cover all 50 districts. The initiative emphasized the segregation of unsold food waste from general waste. Employees used green tape or straw to tie the mouths of food waste bags, enabling district office personnel collecting waste daily to easily identify and utilize it effectively, such as by distributing it to farmers and using it for protein insect farming. In 2024, 1,800 tonnes of food waste were delivered to the Bangkok Metropolitan Administration for beneficial use, helping to reduce food waste sent to landfills by 20 tonnes per day.

Metric used to determine the compensation of executive members

The company cascaded the corporate KPIs to designated functions. A few KPIs are joint KPI for the performances that required cross-functional collaboration for food product leftover and cut-down food waste from stores. The executives including Vice President of Operation who takes part of store ordering, General Manager of Merchandise division who in charge of the customers' needs, and Senior General Manager of store operation development division who analyzes the store ordering. To achieve this target, it reflects in their 10%, 10%, and 3% weight in the respective executives’ performance evaluation (KPIs).

Waste reduction training provided to employees

CP ALL emphasizes on raising awareness and providing knowledge to employees on waste management and reduction throughout all work processes, from upstream to downstream. This includes production processes, storage, transportation, distribution, and sales to maintain product quality, safety, and consistency. This will help reduce waste in the company's operations through training, knowledge sharing, and promotional activities as follows:

Sustainability Performance Data 2O24 : Environment

Waste Disposal

| Unit | FY 2021 | FY 2022 | FY 2023 | FY 2024 | Target for FY 2024 | |

|---|---|---|---|---|---|---|

| Total waste recycled/ reused | Metric tonnes | 160,099.76 | 154,818.97 | 104,890.74 | 188,147.20 | |

| Total waste disposed | Metric tonnes | 64,933.85 | 58,840.38 | 57,536.34 | 62,564.40 | 65,600 |

| - Waste landfilled | Metric tonnes | 61,600.88 | 55,196.83 | 53,913.50 | 56,873.35 | |

| - Waste incinerated with energy recovery | Metric tonnes | 3,252.66 | 3,592.39 | 3,582.75 | 5,662.15 | |

| - Waste incinerated without energy recovery | Metric tonnes | 80.31 | 51.16 | 40.10 | 28.90 | |

| - Waste otherwise disposed | Metric tonnes | 0 | 0 | 0 | 0 | |

| - Waste with unknown disposal method | Metric tonnes | 0 | 0 | 0 | 0 | |

| Data coverage (as % of denominator) |

percentage of: Revenue | 95.52 | 100 | 100 | 100 |

Other Information

Performance Data of Sustainable Waste Management

| GRI Starndard | Required Data | Unit | 2019 | 2020 | 2021 | 2022 |

|---|---|---|---|---|---|---|

| 306-3 (a) 2020 | Total waste generated | Tonnes | 174,461.64 | 182,442.19 | 219,409.69 | 207,701.67 |

| 306-4 (a) 2020 | Total waste diverted from disposal | Tonnes | 126,259.35 | 125,688.45 | 159,023.78 | 153,194.14 |

| 306-4 (b) 2020 | Hazardous waste | Tonnes | 18.35 | 59.40 | 48.26 | 205.18 |

| - Recycling | Tonnes | 17.89 | 45.83 | 24.81 | 186.31 | |

| - Energy recovery (used for mixed fuel) | Tonnes | 0.46 | 13.57 | 23.45 | 18.86 | |

| 306-4 (c) 2020 | Non-hazardous waste | Tonnes | 126,241.00 | 125,629.04 | 158,975.52 | 152,988.97 |

| - Reused | Tonnes | N/A | 90.28 | 82.33 | 367.64 | |

| - Recycling | Tonnes | 119,780.06 | 117,194.78 | 149,385.17 | 139,798.98 | |

| - Composting | Tonnes | 6,460.94 | 6,613.28 | 7,254.84 | 10,058.43 | |

| - Energy recovery (used for mixed fuel) | Tonnes | N/A | 1,730.71 | 1,963.33 | 2,667.67 | |

| - Others (animal husbandry) | Tonnes | 0 | 0 | 289.86 | 96.25 | |

| 306-5 (a) 2020 | Total waste directed to disposa | Tonnes | 48,202.29 | 56,753.74 | 60,385.91 | 54,507.52 |

| 306-5 (b) 2020 | Hazardous wast | Tonnes | 25.84 | 12.74 | 83.28 | 214.04 |

| - Incineration | Tonnes | 20.20 | 7.29 | 74.89 | 14.25 | |

| - Landfill | Tonnes | 5.64 | 5.45 | 8.39 | 199.80 | |

| 306-5 (c) 2020 | Non-hazardous waste | Tonnes | 48,176.45 | 56,741.00 | 60,302.64 | 54,293.48 |

| - Incineration | Tonnes | 1,778.93 | 0 | 5.41 | 36.91 | |

| - Landfill | Tonnes | 46,397.52 | 56,741.00 | 60,297.23 | 54,256.57 | |

| Percentage of total waste diverted from disposal per total waste generated | Percentage | 72 | 68.89 | 72.47 | 73.75 | |

| 306-3 (c) 2020 | Total food waste | Tonnes | 58,864 | 65,347.90 | 66,983.07 | 64,410.08 |

| - Fruits and vegetables | Tonnes | N/A | 7,764 | 19,899.06 | 21,304.13 | |

| - Meats and seafood | Tonnes | N/A | 6,408 | 3,766.27 | 4,534.33 | |

| - Dairy | Tonnes | N/A | 2,381 | 2,315.32 | 3,582.20 | |

| - Ready to eat (RTE) | Tonnes | N/A | 22,106 | 18,041.47 | 16,959.04 | |

| - Beverage | Tonnes | N/A | 1,794.25 | 1,265.83 | 1,503.45 | |

| - Process food | Tonnes | N/A | 1,076.70 | 655.59 | 1,962.90 | |

| - Bakery | Tonnes | N/A | 15,235.46 | 12,593.43 | 14,252.95 | |

| - Others | Tonnes | N/A | 8,582.51 | 8,446.11 | 311.08 | |

| 306-4 (a) 2020 | Food waste utilization | Tonnes | 17,943 | 18,033.87 | 12,611.83 | 16,260.86 |

| - Delivered for further consumption (Reduce) | Tonnes | N/A | 0 | 0 | 0 | |

| - be used as animal feed (Reuse) | Tonnes | N/A | 17,476.17 | 12,014.58 | 14,926.75 | |

| - reuse making fertilizer, biogas (Recycle) | Tonnes | N/A | 59.91 | 508.76 | 1,321.16 | |

| - นused to produce energy (Energy Recovery) | Tonnes | N/A | 497.80 | 88.49 | 12.94 | |

| 306-5 (a) 2020 | Total food waste directed to disposal | Tonnes | 40,921 | 47,314.02 | 54,371.24 | 48,149.21 |

| - Landfill | Tonnes | N/A | 47,314.02 | 54,371.24 | 48,149.21 | |

| Food waste prevention | Tonnes | N/A | N/A | 21,314.71 | 31,230.11 | |

| - Order optimization | Tonnes | N/A | N/A | 5,079.31 | 7,293.17 | |

| - Material for new product | Tonnes | N/A | N/A | 1,969.00 | 9,848.36 | |

| - Animal feed | Tonnes | N/A | N/A | 14,225.00 | 13,740.13 | |

| - continue consumption (Reduce) | Tonnes | 0 | 0 | 41.40 | 348.45 |

Breakdown food waste data set was sub-set of and included in total waste generated which is presenting above

Related Policy and Guideline

| Food Loss and Waste Management Policy | Download |